Small Block Chevy Build Up

Here are a series of shots of another 355 cubic inch Chevy build.

Block has been rough cleaned by us…then cleaned again by the machine shop, then bored then we clean it AGAIN when we get it back. Here trial assembly beginning… Second picture, all pistons in to check deck height

This deck bridge is used to find TDC then check deck height. Piston rock has to be factored in….The reason for this is to determine whether the block will be decked or a custom piston will be used to get the quench distance where we want it for the specific build or if simply using a specific head gasket thickness will get it where we want to be.

The customer supplied his own cam and heads. The heads came supplied with the valve springs installed. These springs may or MAY NOT be ideal for proper valve control with his chosen cam USUALLY NOT for serious engines! Here I am checking the installed height with this height micrometer or “mike”

Then the spring seat pressure is checked…. These are 180# seat pressure

Then the open pressure is checked…..

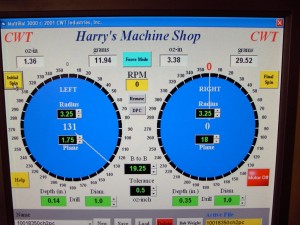

I use my machine shop of choice for balancing because they do it REAL….they don’t just the advertised piston and rod weight for the bob weight….They weigh EVERY rod, ring pack, rod bearing and piston… All the pistons and rods are weighed

Setting up the bob weights…..Here you can see that the front was almost 30 grams out……Now listen up……..

I’ve said this before and now here is the PROOF…..If you buy a rotating assy. and they CLAIM it is already balanced, that is okay for a 350-400 horse motor….BUT for a 400+ HP motor you BETTER GET IT BALANCED…..

Here is the deal…as you see above, to truly balance a motor you MUST weigh every piston, rod, ring, bearing and spiroloc!!! When you buy a balanced rotating assembly they simply look at the piston part number and the rod part number and use the ADVERTISED SUPPOSED weight and add a bit for the weight of the rings & bearings and use this figure for the bob weight, whoever does their balancing does not even HAVE the pistons and rods there to weigh them!!!!

THIS WAS A “BALANCED” assembly and three of the pistons had to be lightened and the assy was almost 30 grams out!!!!

The ONLY WAY you have purchased a REAL balanced rotating assy. is if they HAVE all the parts, weigh them, then balance it and sell you the pistons, rods, rings, AND bearings all together….AND the flywheel & balancer if it is an external balance setup!

I have guys ask all the time why not just buy a crate engine due to the lower cost….Well there is a good reason crate engines have a lower cost. I have had the opportunity to examine a few crate engines and their clearances and assembly is downright SCARY in some cases! SOME of them were easy to examine….the parts supposed to be inside the engine were OUTSIDE the engine…or could be seen easily through the big hole in side of the block!

Here is an example of a crate engine that dropped a valve… This can be caused by MANY things…from too high exhaust temp from excessive timing retard or maybe insufficient piston-to-valve clearance depending on if it is an intake or exhaust valve (among many other causes)….But on a mass assembled crate engine it’s most likely cause is due to improper valve geometry or not enough valve spring pressure…..

Here is an example of a crate engine that dropped a valve… This can be caused by MANY things…from too high exhaust temp from excessive timing retard or maybe insufficient piston-to-valve clearance depending on if it is an intake or exhaust valve (among many other causes)….But on a mass assembled crate engine it’s most likely cause is due to improper valve geometry or not enough valve spring pressure…..

Many think that high spring pressures are hard on valves, but valves that bounce excessively upon closing due to too WEAK of valve spring pressure is MUCH harder on the valves…THIS above picture is usually the result…Believe me, a crate engine will NOT save you money…matter of fact they will COST you MORE in the long run if used for anything more than a car show cruiser…..Crate engines are usually assembled with cheap overseas parts and are assembled with a pre-determined part number valve springs etc…which may be the right part number for a cruiser that sees only 4 or 5 drags a year, but is nowhere NEAR the right part for the guy that will go to the track every other weekend and/or “race by himself” on the street every chance he gets turning the sucker 8,000 RPM with no load on the engine due to tire spin!! Yea ya’ll know who ya’ll are!

After decking the block I re-chamfer all the bolt holes….Like so…to remove the sharp edge….if not they will be subject to cracking around the bolt holes…

Here I’m chasing all the bolt hole threads with a bottom tap…

Here the block has been cleaned AGAIN…Here it is trail assembled AGAIN to check deck height after decking….next comes the cc-ing process to determine the TRUE static compression ratio in order to spec out the proper camshaft selection….

Here I’m cc’ing the head chambers. I use a class A buret and the plate has been lapped to assure it is perfectly flat to achieve utmost accuracy. These Dart Pro 1 heads are ADVERTISED as 64cc but that NEVER happens!

Here I’m getting ready to check the piston dome volume, head gasket volume and the deck volume….But first I have to check the volume of the plate…this volume changes with temperature so it must be checked every time. In the second pixcture I have the piston at TRUE TDC and have filled the plate….The head had already been installed and torqued to compress the head gasket…. Then I subtract the amount from the amount of volume the plate holds.