Feeding the Fuels Needs of a Procharger

This is a fuel pump modular assembly from a 2003 GMC Denali. The customer installed a Procharger supercharger and has been having fuel delivery problems….He brought us this module to install for him….

He tried to install twin 255lph pumps in an attempt to duplicate what hotrodders have done for a few years now with the 5.0 Mustang and the LS1 Camaro. Ford is doing this now on the Supercharged pickups.

It was a valiant effort on his part, but it just wasn’t gonna happen….see that tab on the module in the left picture….it has to line up with that slot on the tank in the center picture….Well when you did that the arm for the fuel gauge was aimed at the side of the tank as shown in the right picture….With the orientation of fittings he used the module upper and lower half could only go together one way…..And that way was clocked wrong for the gauge arm to work….His assembly would not fit in the tank, it was THAT simple….Long story short we had to start from scratch and just do it as if he would have taken it to us first to do it the way we do them here….

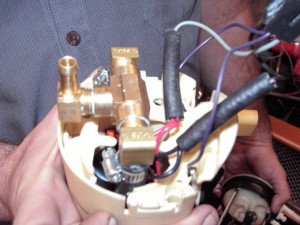

This is the conglomeration of fittings we found when we opened it up….

Here was another issue that we didn’t see at first, but realized when we did it our way….The tank is 8 5/8 deep…. Notice the springs on the stock unit….they have to be there to allow the unit to “grow”….

See the fuel tank is plastic….as you fill the tank, it stretches and gets “deeper”……When these units are modified with twin pumps you have to put them back at a “fixed” length…..When you do this you have to use the measurement of the tank when empty….Their unit measured the same as the stock unit, but they matched the uncompressed overall length…..There is no way their unit would have fit in the tank anyway…..

Our design more closely matches the Ford design….We were completely out of nylon Y’s we usually use for this, but I scrounged up this brass T and used it so the dude could have his truck back…It would have been 2 weeks before I would have received the Y’s as this was done the Friday before Christmas…

We set the depth at 8 1/2″ to keep the pumps off the bottom of the tank even at low fuel levels….When the tank is full the pumps will be even farther from the bottom of the tank but this has to be this way too keep from starving the pumps due to being too close to the bottom of the tank at low levels when the tank is “shallow” Here we are trial fitting everything…

We used screws to attach the outer shell the gauge mounts on to the rods coming out of the upper half….In the second picture, the unit is all ready to put back in the tank….The only drawback to this is that with the fixed length now, the fuel tank capacity will be the same BUT the “usable” amount of fuel will be approximately 3-4 gallons less…

This is the business end of the truck…..

Here are a few shots of the Denali from above. The 2003’s did not come factory with the electric fans, so the guy bought the blades, motors, and shroud from GM for the later model truck and had us create a setup that works just like the factory late model fans in every way!

First off, the factory computer has the ability to control the fans, but the strategy is not “turned on” from the factory and the wires for fan control are not present in the factory 2003 harness. So the strategy was programmed to enable fan control in the PCM….

Then I removed the pins and wire from and old connector I had laying around….I even used the factory wire color!

Then I installed the pins into the proper cavities in the PCM harness connectors….One wire is the high speed fan control and the other is the low speed fan control.

There is no harness available from GM for the factory fans at the time I did this, (that would have been waaay to easy!), so I had to build the harness per the factory wiring diagram using 3 Bosch 30 amp relays.

The way this is wired when the low speed fan control turns on it runs both fans in series….this causes a voltage drop which runs the fans slow…..when the high speed fan control is active it switches the current path to a parallel circuit providing full battery voltage to the fans and they run at high speed. The fans run at low speed as well any time the A/C compressor is on. This duplicates the operation of the late models that come factory with electric fans perfectly. The only difference is that the on and off temperature values were changed in the PCM strategy and the fans come on at a lower temp! That is sexy right there……So if you have a late model truck or SUV and have done engine mods, we can hook you up with a factory operational electric fan system!